Thanks to the microprocessor control and adjustment of the dosage this machine is able to facilitate and quicken the injection of the fillings inside the pralines. The piston pump body is built...

More details

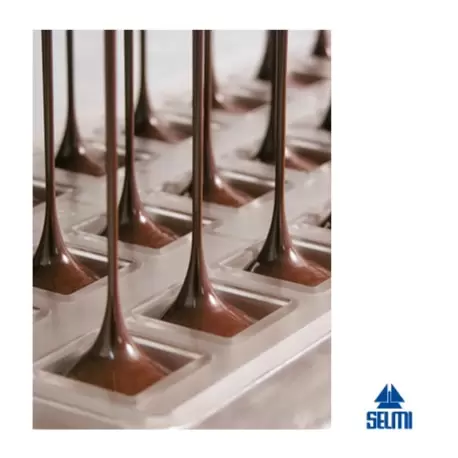

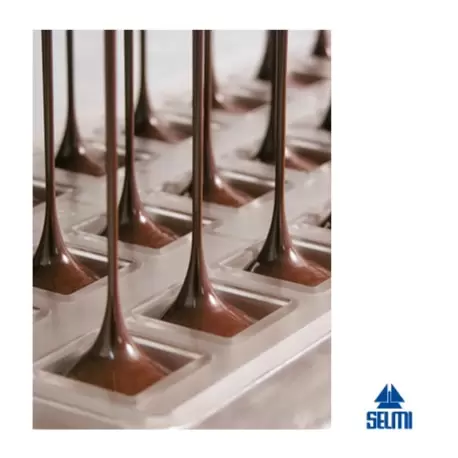

Thanks to the microprocessor control and adjustment of the dosage this machine is able to facilitate and quicken the injection of the fillings inside the pralines. The piston pump body is built with a completely cleanable material.

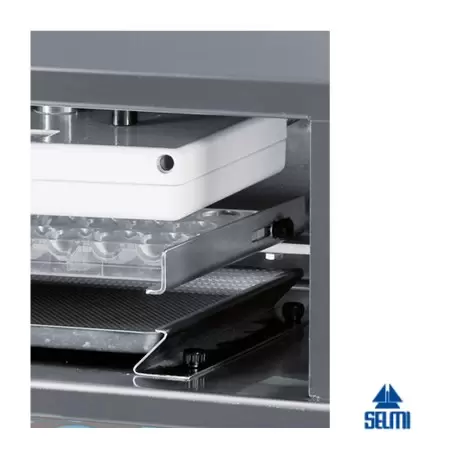

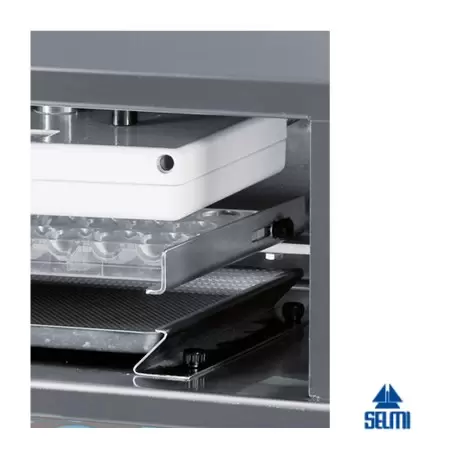

The working environment at the point of injection is heated and thermoregulated. If the Filler is used with low density fillings it can reach high levels of productivity. The mould is placed on a vibrating table to optimise the

injection of the fillings, thus eliminating air bubbles which could compromise the shelf life of the product. The filling production of this machine can reach 300 moulds/hour.

TECHNICAL DATA:

Tank capacity 6 Kg For the Filler praline

Power consumption 1.4 Kw - 220 volt single phase.

Dimensions h. 580 mm., w. 950 mm., d. 370 mm.

For the praline model.

Filling speed 6 moulds per minute, for the praline

IT NEEDS TO BE CONNECTED TO A COMPRESSED AIR SUPPLY

CHARACTERISTICS:

• High productivity of moulded chocolate.

• Injects liquid fillings (having a max viscosity of chocolate).

• Dosage via custom made injection plate.

• Piston calibrated dosage.

• The machine can be used for filling with spreads.

Write a review

Write a review

check_circle

check_circle